“JIS Weather-Resistant Steel Centered on SMA Materials”

- Product

- COR-TEN

This time, I will write about JIS weather-resistant steel, focusing on SMA materials.

※)JIS (Japanese Industrial Standards) are a set of standards used in Japan for industrial activities. They cover a wide range of products and services, ensuring quality, safety, and efficiency. These standards are developed by the Japanese Industrial Standards Committee (JISC) and are crucial for maintaining consistency and reliability in manufacturing, engineering, and construction.

JIS Weather-Resistant Steel

Among JIS weather-resistant steel plates, the most commonly used is JIS G3114 ‘Hot Rolled Atmospheric Corrosion Resisting Steels for Welded Structure.’ It is mainly applied to bridges but is also used in architectural applications.Additionally, there are weather-resistant hot-rolled steel plates in JIS G3125 ‘High Weather Resistant Rolled Steels’ and JIS G3140 ‘High Yield Point Steel Plates for Bridges.

For applications with high public significance, such as bridges, the use of JIS materials is a prerequisite. It is generally required to have a mill sheet that certifies the material as JIS.

Types of Weather-Resistant Steel

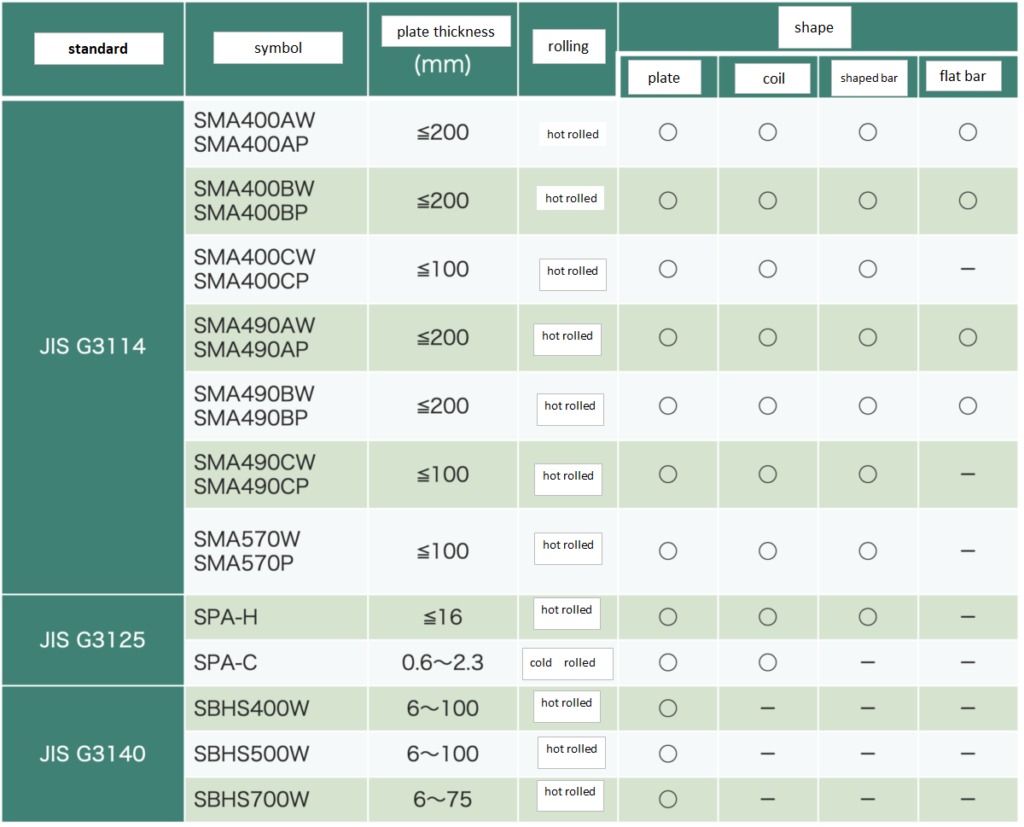

Table 1 summarizes the types of weather-resistant steel and their thicknesses. The thickness is specified to quite a considerable extent. Although the weather resistance itself is due to the dense protective rust formed on the surface, which suppresses further rusting, the internal material also needs to be important for its use as a strength member. Therefore, even though the internal part doesn’t need to have weather resistance, it is specified this way.

Main Chemical Components

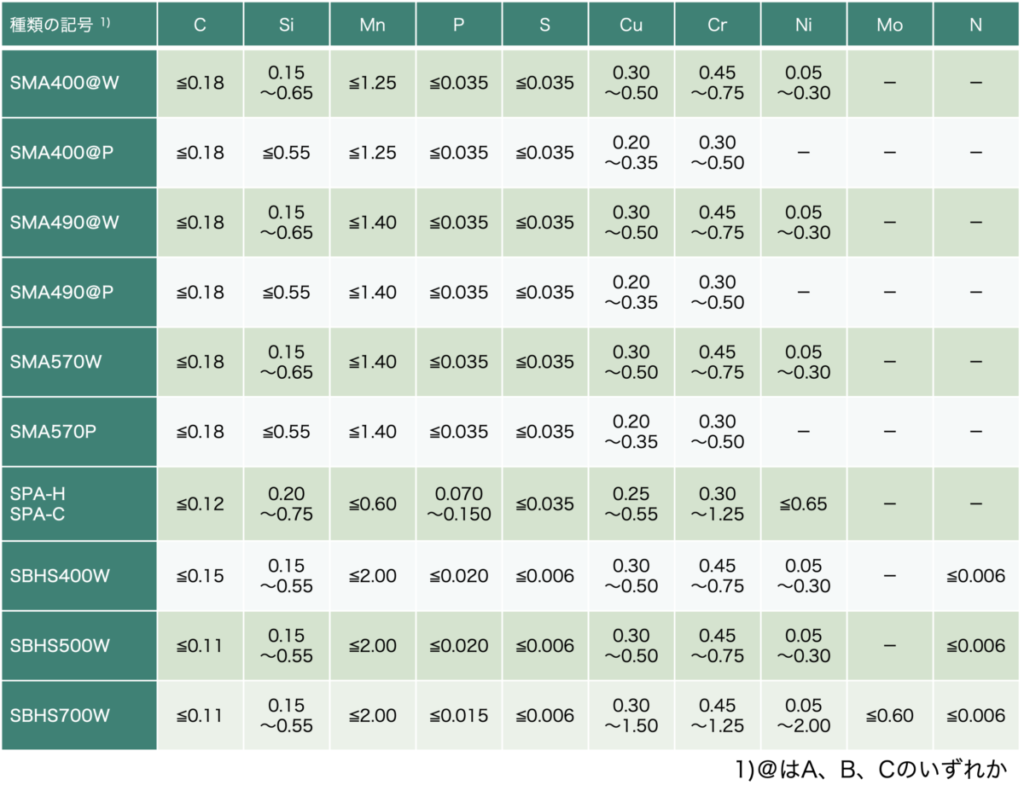

Table 2 shows the specification of components.

The main elements effective for weather resistance are P, Cu, Ni, and Cr, and regulating the content of these elements is the key point. Other elements are regulated to ensure quality such as strength, toughness, and weldability. While P is a useful element for weather resistance when added in large quantities, it adversely affects toughness and weldability. Therefore, it is actively added only in SPA-H and SPA-C, and the upper limit of plate thickness is also regulated.

Here, I will explain the differences between SMA○○○○W and SMA○○○○P in JIS G3114.

The JIS standard states that ‘steel materials with the suffix W are typically used without painting or with rust stabilization treatment, while steel materials with the suffix P are typically used with painting.’ This illustrates that there are three basic methods for using weathering steel: unpainted, rust stabilization treatment (which is considered a type of unpainted use), and painted.

The original purpose of weathering steel is to form a dense and stable protective rust layer on the surface to slow down the progress of corrosion, so the primary use is unpainted.

On the other hand, painting weathering steel is done with the expectation that the progress of peeling from flaws in the paint will be slow. Since the painted parts do not require weather resistance, as shown in Table 2, the elements that provide some weather resistance are slightly reduced, lowering the alloy cost.

However, in public structures such as bridges, painting weathering steel has been deemed undesirable as it provides double corrosion protection. Consequently, steel materials with the suffix P (such as SMA490AP) have become rarely used in recent times.

Outside of public structures, there are many instances where weathering steel is painted, and this has shown advantages. The prime example of this application is containers. Most containers are painted with COR-TEN or SPA-H.

Weldability of Weathering Steel

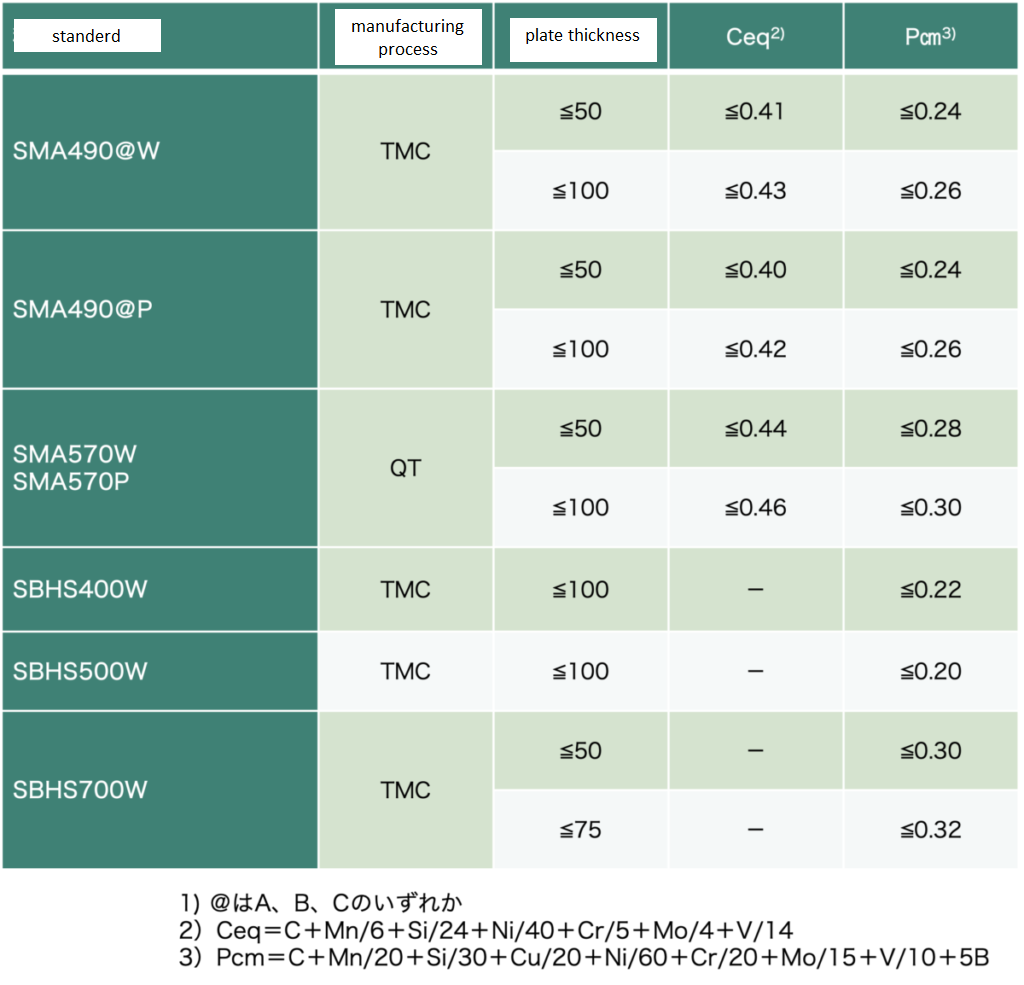

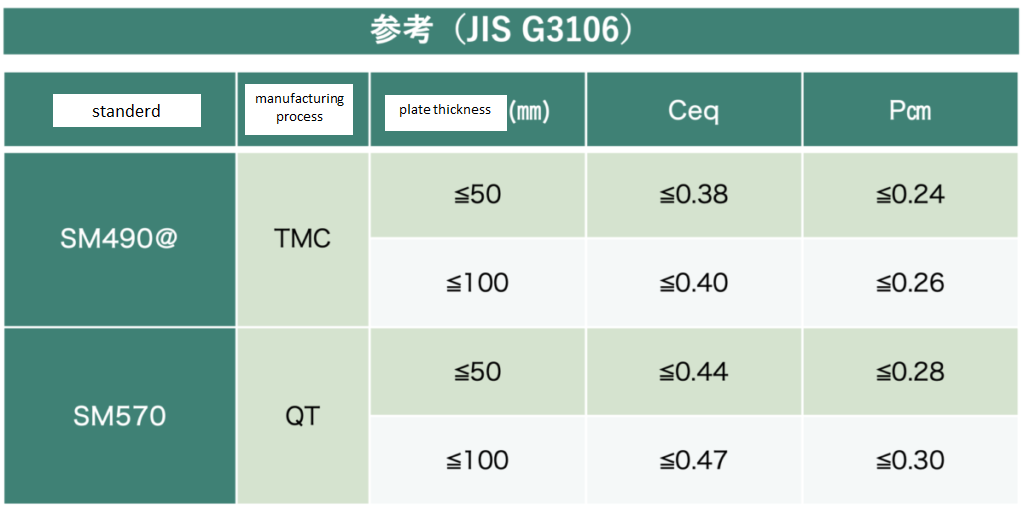

Table 3 shows the regulatory values for weldability, including Carbon Equivalent (Ceq) and Weld Cracking Susceptibility Composition (Pcm). For reference, the regulatory values for SM materials of JIS G3106, which are rolled steel materials for welded structures, are also provided. Although there are slight variations, a comparison within the same class reveals no significant differences.

This is because, although alloys are added as weather-resistant elements, C and Mn are reduced to adjust the strength accordingly. Therefore, it is considered that the weldability of weathering steel does not differ significantly from that of ordinary steel. Additionally, the Pcm of SBHS material in JIS G3140 is kept low, resulting in steel with even better weldability.

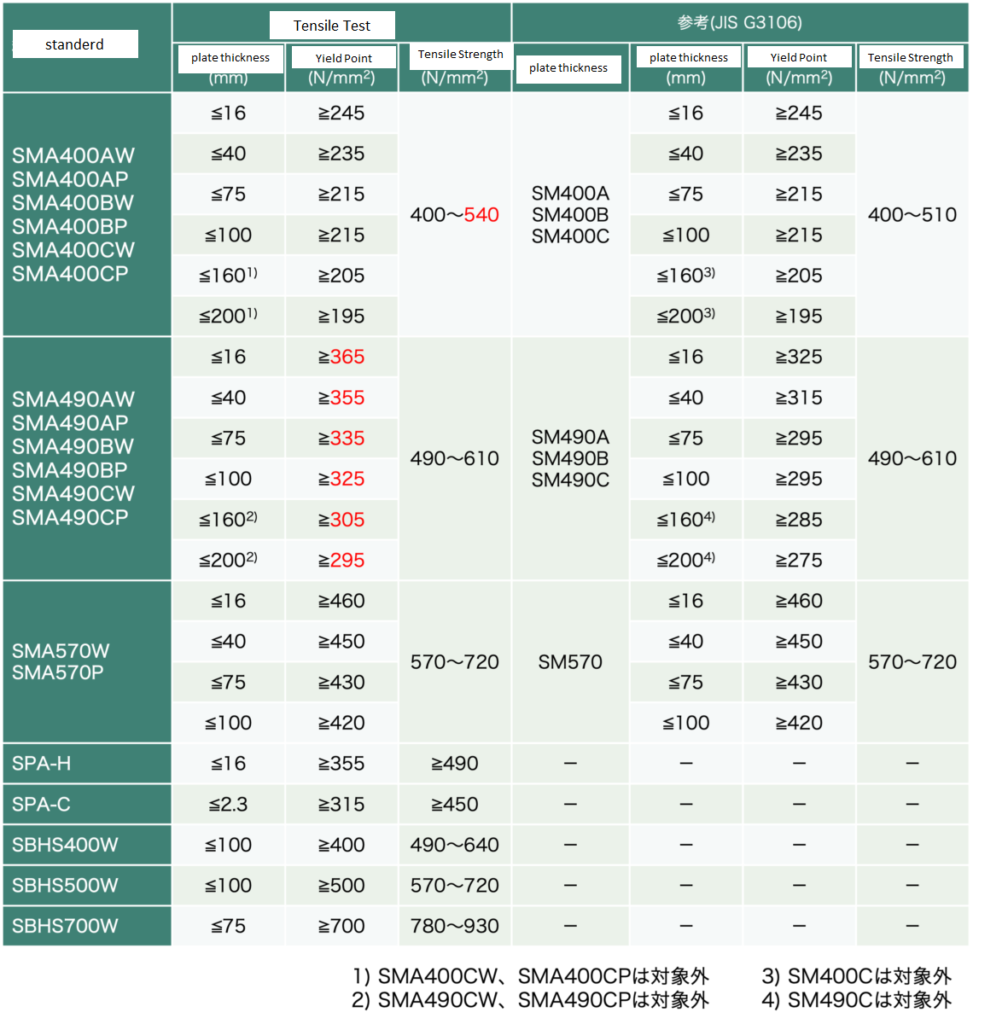

Mechanical Properties of JIS Weathering Steel (Tensile Test)

Table 4 lists some of the regulatory values for the tensile test of weathering steel. For reference, the regulatory values for SM materials of JIS G3106, which are rolled steel materials for welded structures, are also provided. Comparing materials of the same class, it is noted that the upper limit of TS (tensile strength) for the SMA400 class is slightly wider, and the yield point of the SMA490 class is somewhat higher (equivalent to SM490Y). Additionally, the SBHS materials of JIS G3140 are designed with the concept that the yield point is high and consistent regardless of plate thickness.

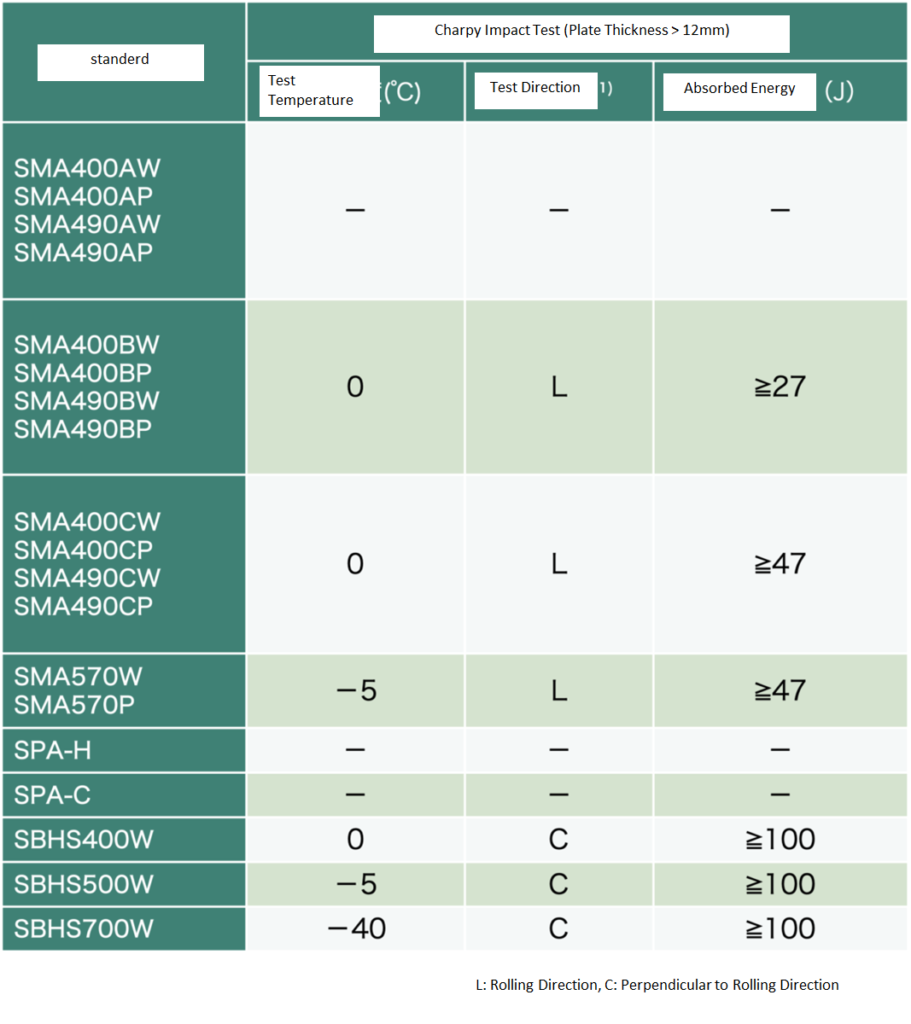

Mechanical Properties (Charpy Impact Test)

Table 5 lists the regulatory values for the Charpy impact test. The target is for plates thicker than 12 mm. The lack of regulation for plates 12 mm or thinner is partly due to the fact that thinner plates do not have as strong structural constraints. Additionally, it is considered that thinner plates inherently tend to have better toughness, so it is believed that they possess sufficient toughness even without testing. This does not mean that toughness is not necessary.

The regulations in JIS G3114 largely follow those in JIS G3106. The toughness is not specified for SPA-H in JIS G3125. Since it contains a large amount of P and its toughness is not favorable, consideration should be given to its application. In JIS G3140, the testing direction is required to be perpendicular to the rolling direction, which tends to have less favorable toughness, and the absorbed energy is set quite high at 100J or more. It can be said that this is a high-grade steel materia for bridges.

On the Welding of Weathering Steel

Weathering steel requires dedicated welding materials. This is because if the welded part does not have the same weather resistance as the base metal, protective rust will not form on the welded part, leading to corrosion.

**”The above is an introduction to weathering steel as specified by JIS.

If you have any questions regarding the selection or processing of steel materials, please do not hesitate to contact us.

Please note that the contents of this article are our company’s view and do not guarantee everything. When purchasing or processing products, please confirm with professional companies, including ours, and verify the materials according to your purpose and usage.“**

We are a specialized trading company based in Japan, dealing in high-tensile steel and other special steels.

Please feel free to contact us.

Feel free to email us.

↓↓↓

mailto:info@kumagai-steel.co.jp