“What is high-tensile strength steel? Benefits of use”vol.2~TMCP Steel & Quenched and Tempered Steel, Charpy Impact Test~

- Product

- WEL-TEN

Up until the last time, we introduced topics such as What is high-tensile steel? and What are the benefits of high-tensile steel?

This time, we will explain the following topics.

Table of Contents

- How is high-tensile strength steel made?

- TMCP steel and quenched & tempered steel

- Charpy impact test

- Summary

※The content of this article represents our views and does not guarantee everything. When purchasing or processing products, please consult with specialized professionals, including our company, and verify the material according to its intended purpose and application before use.

1.How is high-tensile strength steel made?

So, how is high-tensile steel made? Here, we will use thick plates as an example to explain the process.

Thick plates are made by heating and rolling a semi-finished product called a slab.

For mild steel, 40 kg steel is produced simply by rolling, but for 50 kg high-tensile steel…

① Further increasing alloy elements such as manganese to enhance strength

② Enhancing strength by lowering the rolling temperature or rapidly cooling with water immediately after rolling

There are such manufacturing methods.

2.TMCP steel and quenched & tempered steel

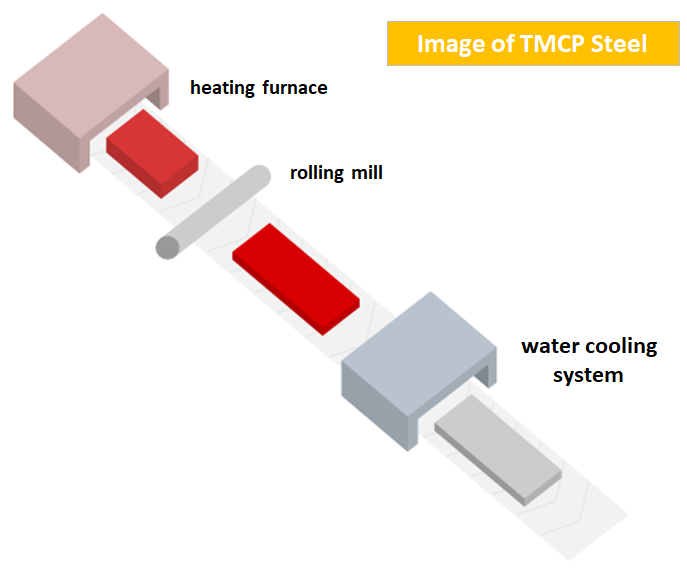

Steel produced using method ② above is called TMCP steel.

TMCP steel” (Thermo-Mechanical Controlled Process steel)

It stands for “Thermo-Mechanical Control Process”. In addition to composition adjustment, it involves controlling heating and rolling temperatures, and in many cases, performing online water cooling immediately after rolling.

For 50 kg-class steel used in shipbuilding, this method has been adopted for over 40 years.

By reducing alloy elements, weldability has significantly improved.

Even for SM490-class welded structural steel, which is standardized in JIS—a set of standards designed to unify and improve the quality of industrial products in Japan—TMCP production has recently become the mainstream method.

Quenched and tempered steel

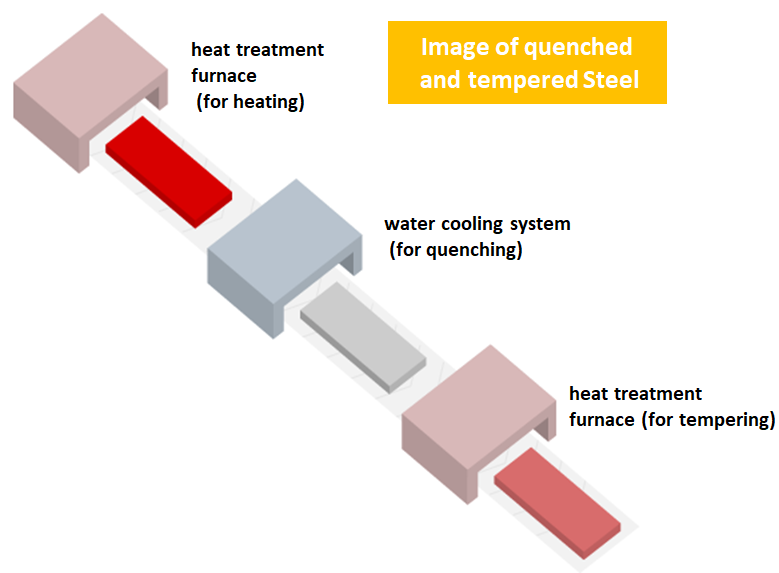

For high-tensile steel of 60 kg or higher, it was traditionally produced by applying a quenching and tempering (QT) heat treatment to the steel plate.

This process takes advantage of iron’s property of hardening when rapidly cooled.

For 80 kg steel and above, quenching and tempering is still the mainstream method today.

Steel produced through quenching and tempering is called quenched and tempered steel.

It refers to adjusting properties such as strength and toughness through heat treatment.

When you hear quenching, you might imagine heating iron and then quickly dipping it into water with a sizzling sound.

However, in steel manufacturing, where large-scale heat treatment is required, production capacity is limited.

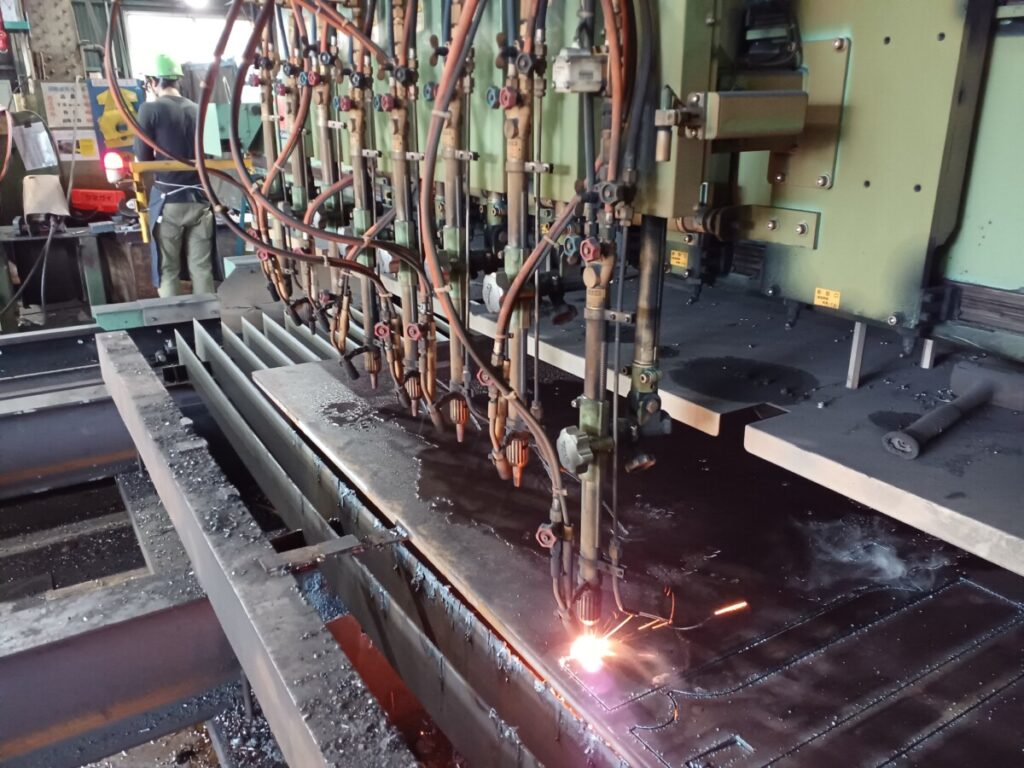

Instead, the process involves heating the steel to around 900°C in a heat treatment furnace, then cooling it by spraying water forcefully from above and below.

Compared to submerging in water, a continuous supply of fresh, high-pressure cold water allows for an even faster cooling rate.

The steel plates move through the heat treatment furnace, gradually increasing in temperature. Then, as they continue along the production line, they pass through a water-cooling zone, making the process highly efficient.

Mill scale (oxide scale)

Let’s talk about the surface condition of heat-treated materials.

In most cases, shot blasting is used before heat treatment to remove the mill scale, an oxide layer that forms during rolling.In the heat treatment furnace, the oxygen level is reduced (by filling the furnace with nitrogen) to minimize the formation of surface oxides (scale).There are various reasons for this, but one key factor is maintaining surface uniformity during water cooling to prevent inconsistencies.As a result, heat-treated materials tend to have a thinner and more uniform mill scale on the surface.

Recently, even for 60 kg-class steel and above, methods such as controlling the rolling temperature or achieving a quenching effect by water cooling immediately after rolling on the production line have been adopted.

These steels are sometimes called non-quenched and tempered steel because they are not heat-treated, or they may also be referred to as TMCP steel, similar to 50 kg-class steel.

For 60 kg-class steel, which is produced through composition control and rolling, Nippon Steel markets it as ‘WEL-TEN 590RE’.

Difficulty of Hardness Control

Recently, the use of high-tensile steel for thin sheets in the automotive industry has been advancing, but the adoption of high-tensile steel was initially led by thick plates.

One of the challenges in adopting high-tensile steel for thick plates is controlling thickness deviation in the plate’s thickness direction.

For example, when water-cooling a steel plate with a thickness of 100 mm, the front and back surfaces cool within seconds, while the center of the thickness takes several minutes.

As a result, the hardening process differs significantly between the surface and the interior of the plate.

However, with proper composition adjustments, it is possible to control the hardness to be similar, even if the cooling rates differ significantly.There is an index called the hardenability factor, which indicates a method to achieve hardness even at slower cooling rates. Elements such as chromium (Cr), molybdenum (Mo), and nickel (Ni) enhance hardenability.

Also, adding just 0.001% of an element called boron (B) to steel can produce noticeable effects. Iron is truly fascinating, isn’t it?

3.Charpy impact test

Alongside the tensile test, the Charpy impact test is also crucial.

Simply put, it determines whether the steel is brittle and easily breakable.

Glass, for instance, is hard but weak against impacts, and it shatters when struck with a stone, right?

When the temperature drops, steel also becomes brittle and more prone to breaking upon impact. For example, while it may not break in the peak of summer in Okinawa, it can shatter in the depths of winter in Hokkaido.

For this reason, the Charpy impact test is specified in the standards for some types of steel to define its toughness, alongside the tensile test.When subjected to an impact, brittle materials shatter with little energy, whereas tough materials require a lot of energy to break. Think of it like reinforced glass, which might serve as a good analogy.

Steel that is difficult to break is referred to as ‘tough steel.The energy required to break it under certain conditions is specified, and the higher the energy at low temperatures, the tougher the steel is considered to be.

In the case of SM490B, a JIS steel, it is required to have at least 27 joules (J) in tests conducted at 0°C.

For SM490C, it is required to have at least 47 joules.

Thus, SM490C is superior in terms of toughness.

The values of 27 joules and 47 joules themselves are determined based on empirical rules from past failure cases. For cold regions, tests at even lower temperatures can be specified.

By the way, SM570 requires a test at -5°C with a toughness of at least 47J. Although 60-kilo steel is not intended for use in low-temperature environments, why is the test conducted at -5°C?

Generally, as strength increases, materials tend to become more brittle and their toughness decreases. However, in this case, higher toughness is required. For example, JIS SHY685 and Nippon Steel’s WEL-TEN780 series, which are 80-kilo steels, undergo tests at -20°C.

When the plate thickness increases, tests at lower temperatures may be conducted. Using high-strength steel results in greater forces acting on the material, and thicker plates experience more constraint (less force distribution), so it’s necessary to improve toughness.

| JIS standards and manufacturer-branded products | Test temperature | Absorbed energy |

| SM490B | 0℃ | 27J |

| SM490C | 0℃ | 47J |

| SM570Q WEL-TEN590RE | -5℃ | 47J |

| SHY685 WEL-TEN780 | -20℃(-15℃ ※1) | 47J |

| WEL-TEN950 | -25℃(-20℃ ※2) | 47J |

4.Summary

We have introduced more detailed information to understand the basics of high-tensile steel, including manufacturing methods tailored to performance such as TMCP steel and tempered steel, as well as the Charpy impact test.

Next time, we plan to provide useful information for actual use, such as the standards system and its explanations, and points to be aware of during processing and welding.

We are a specialized trading company based in Japan, dealing in high-tensile steel and other special steels.

Please feel free to contact us.

Feel free to email us.

↓↓↓

info@kumagai-steel.co.jp