“What is high-tensile strength steel? Benefits of use”vol.1

- Product

- SM material

- WEL-TEN

Table of Contents

- What is high-tensile strength steel?

- Advantages of high-tensile strength steel

- Summary and Preview

※)The content of this article represents our views and does not guarantee everything. When purchasing or processing products, please confirm with specialized professionals, including our company, and use the material based on verification according to its intended purpose and application.

1.What is high tensile strength steel

Steel with a tensile strength of 40 kg is referred to as mild steel, while steel with a tensile strength of 50 kg or more is called high-tensile steel. As the name suggests, it has a higher strength to withstand tension.As high-tensile steel, there are types such as 50 kg steel, 60 kg steel, 80 kg steel, and 100 kg steel. Currently, the upper limit is around 120 kg steel.

There are hard materials called wear-resistant steel that reach 150 kg, but they are not recommended for use as structural steel in strength members.

By the way, terms like “50 kg steel” are common names.

Originally, in Japan, steel materials capable of withstanding a tensile strength of 50 kilograms per square millimeter (50 kg/mm²) were designated as “SM50,” and those capable of withstanding 58 kilograms were designated as “SM58” under JIS standards. This classification was established around the 1950s to 1960s.

Later, in 1988, Japan adopted the International System of Units (SI units), changing 50 kgf/mm² to 490 N/mm², and the designation was updated to “SM490.”

“Yield strength”

Tensile strength includes “tensile strength” and “yield strength.”

Yield strength is the point at which steel begins to undergo plastic deformation under load. When you bend a piece of steel and it returns to its original shape after releasing it, this is within the elastic range—before reaching the yield point.

Once the yield point is exceeded, the steel will no longer return to its original shape. A nail bends permanently because it has surpassed this yield point.

In structural design, deformation of a structure is a problem, so calculations are based on the yield point. In this sense, yield strength can be considered even more important.

In Japan, materials like SM490, which indicate tensile strength (TS), are standardized under JIS. However, in other countries, many standards use yield strength (YS) in their names. Nippon Steel’s 80 kg steel is called “WEL-TEN®︎780,” whereas overseas, the name typically follows a format like ○○○○690, based on the lower limit of YS.

Even among JIS standards, relatively new specifications such as Steel for Bridge High-performance Structure (SBHS) and Steel for High-Yield Strength Welded Structures (SHY) emphasize yield strength. In these standards, the lower limit of the yield point is reflected in the specification name.The JIS 80 kg steel is designated by the standard code SHY685.

For boiler and pressure vessel steel, SB is based on TS, while SPV is based on YS, which can be quite confusing.

(WEL-TEN is a registered trademark of Nippon Steel.)

2.Advantages of high-tensile strength steel

So, what are the benefits of using high-tensile steel?

The tensile strength of 40 kg steel and 80 kg steel differs by about a factor of two, but in terms of yield strength, the difference is nearly three times. Naturally, higher strength allows for thinner plate thicknesses. Reducing plate thickness also results in lighter weight, which is a significant advantage.

The topmost broadcasting tower of Tokyo Skytree uses 80 kg high-tensile steel. Since high strength is required to support the antenna, using thicker plates would make the upper part of the tower heavier. This, in turn, would require the lower sections to be even stronger, increasing the overall weight of the structure. By using high-tensile steel, this weight increase can be avoided.

In addition, for crane trucks that lift loads to great heights, the boom—the extendable tube—becomes thinner toward the tip.In terms of strength, high-tensile strength steel is used. After all, if the crane itself becomes too heavy, it would be inefficient for lifting heavy loads.

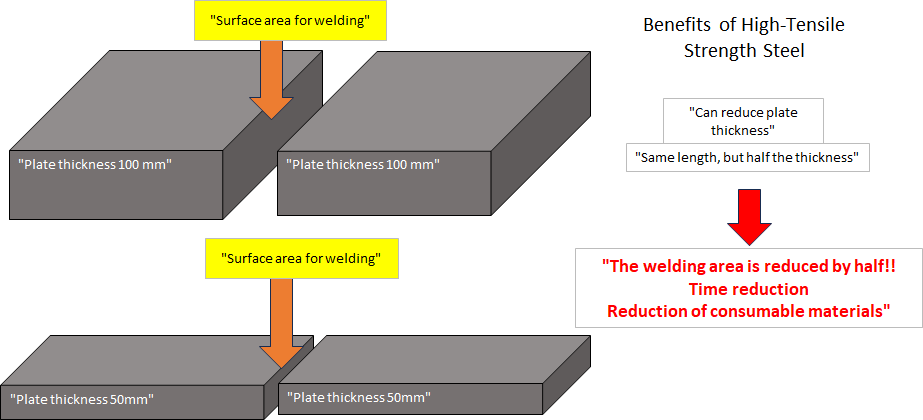

Benefits of welding

When the plate thickness is reduced, there is a benefit beyond just weight reduction—the amount of welding required also decreases.Welding 100 mm plates together requires nearly twice the effort compared to welding 50 mm plates.Welding can be quite a demanding task, right?

3.Summary and Preview

This time, we focused on explaining the basics of high-tensile steel and its benefits.

In future blog posts, we plan to introduce the manufacturing process, testing methods, and standardization system of high-tensile steel.

We are a specialized trading company based in Japan, dealing in high-tensile steel and other special steels.

Please feel free to contact us.

Feel free to email us.

↓↓↓

info@kumagai-steel.co.jp