What is SS400 based on JIS G 3101? vol.2

- Product

- SS400

※)Please note that the content of this article represents our opinion and does not guarantee everything. When purchasing or processing products, please confirm with our company and other specialized professionals, and use the materials after verification according to the purpose and application.

In the previous volume 1, we explained the overview, specified values, standards, and physical properties of SS400.

This time, we will explain important points when actually using it, such as plate thickness, market inventory, and weldability.

Thickness of SS400 Plates

The upper limit of plate thickness is not specified, but considering that SM400A, a welded structural rolled steel in JIS G3106, is specified to be 200 mm or less, and 450 mm or less according to agreements, it seems acceptable to manufacture it beyond that thickness.However, to maintain the lower limit of the yield point, heat treatment (normalizing) is necessary.

Normalizing reduces the grain size, thereby increasing the yield point.There are no lower limit regulations for plate thickness either, but the lower limit for hot-rolled materials is around 1.2 mm. Generally, available thicknesses are approximately 3.2 mm to 150 mm.

For SS400, the dimensional tolerances of steel plates are specified according to JIS G3193.

The standard thickness tolerance is set within the same range of plus and minus relative to the ordered thickness (also known as the nominal thickness), but it is also possible to order with the lower limit set to “0” and double the range on the positive side. However, as will be described later, for stock steel plates, the basic tolerance range is the same for both plus and minus.

These thickness tolerances are finely determined based on the thickness and width of the plate. As the thickness increases and the width becomes wider, the tolerance range also broadens. This standard might be set for the convenience of the manufacturer.

Steel plates generally tend to have greater thickness at the center compared to the sides during hot rolling. This tendency becomes more pronounced with wider widths, hence the tolerances are widened.

This means that the plate thickness tolerances vary depending on the size of the parent material from which they are cut.

For example, a component cut from a parent steel plate with a thickness of 25 mm and a width of 1500 mm has a tolerance of ±0.70 mm, whereas a component cut from a parent steel plate with a width of 1600 mm has a tolerance of ±0.80 mm.

I believe that the thickness tolerances of components are specified separately in the drawings, but it seems contradictory that there are differences based on the parent steel plates when following JIS standards.

This issue is not limited to SS400. However, for pressure vessel steel plates, for instance, the lower limit on the negative side is uniformly set to -0.25 mm, demonstrating some consideration.

Performance and Welding of SS400

Although the standards for SS400 themselves are quite loose, the performance of steel plates manufactured in Japan is relatively high. It seems that the standards align with the Japanese philosophy of the inherent goodness of people. However, if manufactured strictly according to standards, it is possible to have steel materials with considerably poor performance.

Ordinary SS400 is easy to bend and can be deformed through warm or hot processing. Even with heat treatments such as stress relief annealing (SR) or normalizing, it is rare for the strength to fall outside the specified values.

The effect on material properties due to distortion correction by linear heating, etc., is also minimal. However, since the mechanical properties after heating are not guaranteed, care is necessary in cases of high applied stress.

Moreover, general structural rolled steel plates are not intended for welding, but are instead designed to be joined using bolts or other methods.

The steel material intended for welding use is the rolled steel for welded structures in JIS G3106.

However, it is quite common to use SS400 for welding. The Road Bridge Specifications, which are guidelines for the manufacture of bridges, state…

- It is best to apply SS400 to non-welded components in bridges.

- It can be used after investigating the chemical composition in advance and confirming that there are no welding issues through welding procedure tests, etc.

Therefore, in some cases, it is assumed that SS400 can be used for welding.

Over the years, data has accumulated showing that welding does not pose any issues, and it has become commonplace to use welded SS400. However, it is essential not to assume that SS400 can be welded without any problems simply because it is SS400. Proper evaluation and verification must be conducted before use.

Particularly when changing the source of materials or using them for the first time, cautious handling is necessary. Choose a reliable supplier.

About Welding Materials

For welding, use welding materials for mild steel.

When welding SS400 with other steel types such as high-tensile strength steel or corrosion-resistant steel, it depends on the required performance of that section. If corrosion resistance is needed, the appropriate welding material for that requirement is necessary, and if high strength is involved, welding material for high-tensile strength steel is required.

However, generally, if such performance is needed, it wouldn’t be combined with SS400, so welding material for mild steel is often sufficient.

When welding SS400 with stainless steel, there is a concern of welding cracks due to dilution, so please use a dedicated welding material of the 309 series.

Welding SS400 with SC steel is not originally recommended, but if it is absolutely necessary, please use low-hydrogen welding materials and avoid welding cracks with post-weld heat treatment. Using 309 series welding materials is also an option.

In any case, it is essential to recognize the required performance of the weld area and thoroughly verify the quality of the weld.

Stock of SS400

Regarding the sizes of steel plates, if the quantity is sufficient, steel mills will manufacture them in 1mm increments. However, when stocking steel plates in the market, it is generally impossible to stock every size, so standard thickness, standard width, and standard length plates, known as fixed lengths, are typically stocked.

In Japan, standard thicknesses include 3.2 mm, 4.5 mm, 6 mm, 9 mm, 12 mm, 16 mm, 19 mm, 22 mm, 25 mm, 28 mm, 32 mm, 36 mm, 40 mm, 45 mm, 50 mm, and 60 mm, etc. However, we also stock intermediate and thicker sizes, so please inquire.

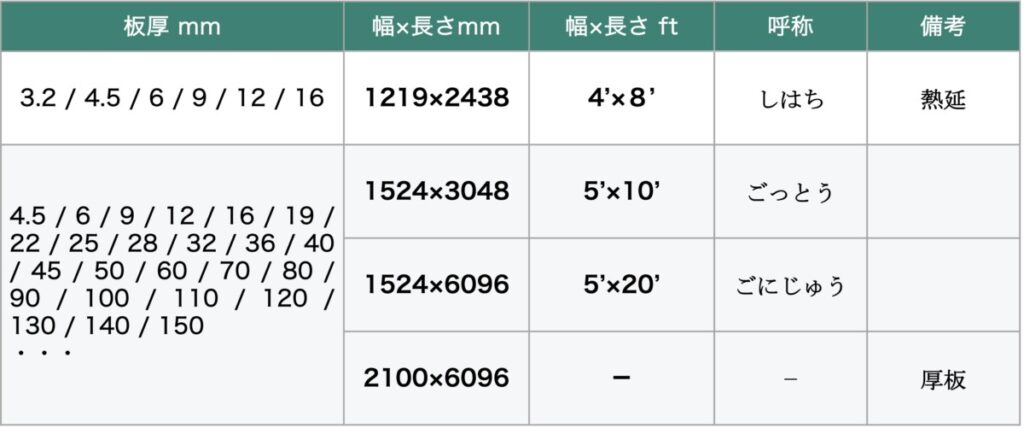

As shown in Table 3, there are many common patterns for width and length, but widths of 2000 mm and 2438 mm are also available. These dimensions are listed in JIS G3193.

A width of 1219 mm is mostly for steel plates manufactured by hot rolling, while widths of 2000 mm or more are often for thick plates. A width of 1524 mm can be either. Additionally, lengths less than 3000 mm are hot-rolled products, and lengths beyond that can be either. Please inquire for sizes other than these widths and lengths.

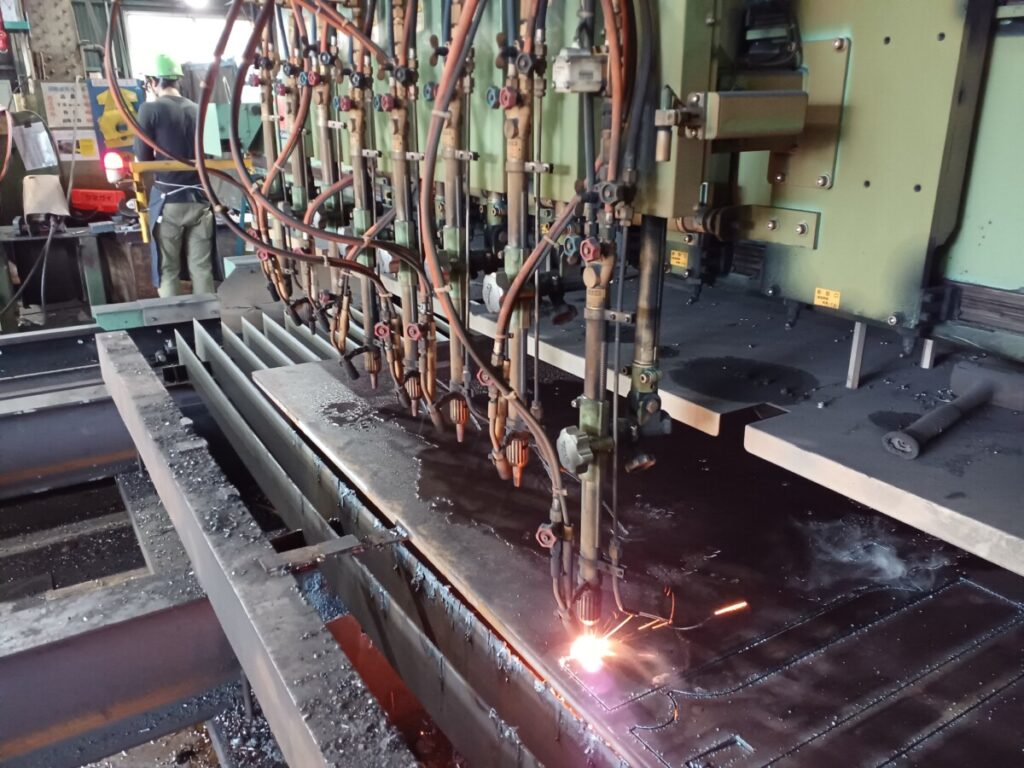

By the way, hot-rolled steel plates are steel plates cut from hot coils manufactured with continuous rolling mills.

Surface Condition of SS400

The surface condition of steel plates, including SS400, generally has an oxide scale called “black scale” attached. The thickness and adhesion of the oxide scale vary depending on the manufacturing method and composition of the steel plate.

Generally, electric furnace materials tend to have thicker and more adhesive oxide scales. In the case of laser cutting, the properties of the scale can affect the cutting quality. Both electric and blast furnace steel plates are manufactured for laser cutting.

Aside from the black scale, in hot-rolled materials, there are steel plates where the black scale has been removed by pickling and then oiled. There are also steel plates where the black scale has been removed by shot blasting, but these are not suitable for stock as they rust easily.

Summary of the SS400 Explanation

Over the past two articles, we have discussed SS400.

Did you find anything interesting? Although our company name is Kumagai Specialty Steel, we also handle base steel materials like SS400. Please feel free to contact us.

We are a specialized trading company based in Japan, dealing in high-tensile steel and other special steels.

Please feel free to contact us.

Feel free to email us.

↓↓↓

mailto:info@kumagai-steel.co.jp