What is SS400 based on JIS G 3101? vol.1

- Product

- SS400

※)The contents of this article reflect our views and do not guarantee everything. When purchasing or processing products, please consult with specialized professionals, including our company, and verify the materials according to the purpose and use.

About JIS

JIS stands for Japanese Industrial Standards. It is a national standard established by the Ministry of Economy, Trade and Industry for industrial products and services in Japan.

SS400 is a type of rolled steel for general structure, specified in JIS G3101. In the JIS numbering system, the alphabet is a department symbol, and “G” represents the steel department. The following four-digit number is the classification number. Starting from the smallest number, definitions of terms, test methods, and analysis methods are listed, and the first steel standard to appear is this rolled steel for general structure.

Regarding JIS materials, there is a certification system for the JIS mark. Only businesses that have received certification can display the JIS mark on their products. Even if a product is labeled SS400, if it does not display the JIS mark, it may simply mean that the company has manufactured it according to JIS standards without being officially certified. It is important to verify whether the product has JIS certification.

About SS400

SS400 includes steel plates, steel strips, shaped steel, flat steel, and steel bars. Here, we will focus on steel plates.

JIS G3101’s rolled steel for general structure includes SS330, SS400, SS490, and SS540. However, SS400 is the most commonly distributed type in Japan, so when people refer to “SS,” they often mean SS400. SS stands for Steel Structure. It is a very widely used standard in terms of steel distribution volume and can be considered a fundamental standard.

SS400 Specifications (Standards)

The composition and mechanical properties of SS400 are specified in JIS G3101.Regarding the composition, as shown in Table 1, only phosphorus (P) and sulfur (S) are regulated. Despite being a fundamental standard, I personally wonder if it’s sufficient for a steel material that is used in large quantities worldwide. In practice, carbon (C) and manganese (Mn) are added to satisfy the mechanical properties.

Due to the lax composition regulations, the composition can vary between companies. It is also possible for different compositions to coexist within the same company. Generally, carbon (C) is contained at around 0.1-0.2%, and manganese (Mn) at about 0.4-1.0%. Phosphorus (P) and sulfur (S) are impurity elements and harmful, so they are significantly suppressed compared to the specified values. In electric furnace materials, elements such as copper (Cu) and chromium (Cr) may be mixed in from scrap, contributing to increased strength. As a result, the carbon (C) and manganese (Mn) content may be slightly lower than in blast furnace materials.

| C | – |

| Mn | – |

| P | 0.050% or less |

| S | 0.050% or less |

| Others | Other alloying elements may be added as necessary |

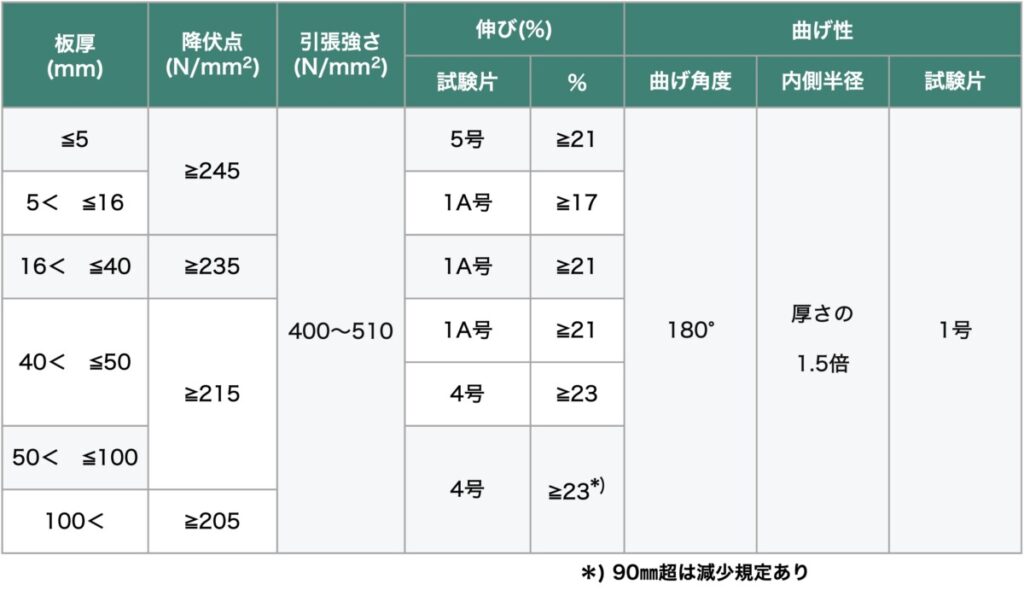

Regarding the mechanical properties, as shown in Table 2, the “400” in SS400 represents the lower limit of tensile strength.

It’s unclear why the arbitrary figure of 41 (kgf/mm²) was initially set, but with the adoption of the SI units, it was changed to the more rounded number of 400 (SS50, conversely, became SS490, which is somewhat arbitrary).

SS400 is commonly referred to as 40-kilo steel and falls into the category of mild steel.

The lower limit of the yield point varies with plate thickness. For thicknesses of 16 mm or less, it must be at least 245 N/mm². As the thickness increases, the yield strength tends to decrease slightly, likely determined for ease of production rather than the required performance at that thickness.

This is also the case with other steel types; differences in the yield point must be accounted for in the design.

Regarding the yield point, when the plate thickness is thin, setting the lower limit of the tensile strength often ensures that the yield point is sufficiently met.

The elongation values vary depending on the shape of the test piece, so the specification is set based on a certain test piece. It seems many people are aware that even if the elongation value (%) is the same, the elongation performance can vary with different test pieces, but not everyone understands this.

The cross-sectional shape of the test piece, whether it is a round bar or a plate, also makes a difference, and the influence of the gauge length, called the original gauge length, which is used to measure elongation, is significant. Test pieces typically undergo necking, a localized deformation that leads to fracture. Due to the large elongation in this necking area, a longer gauge length results in a seemingly smaller elongation percentage.

The bending test for SS400 involves bending the steel plate at an inner bending radius of 1.5 times the plate thickness to 180°, ensuring no surface cracks occur. The width of the test piece is specified to be between 20 and 50 mm.

The thickness is usually the thickness of the plate itself. In the case of standard SS400, cracks do not often occur even with a smaller bending radius, and it is rare to fail the bending test. Therefore, unless required, the bending test can be omitted. In actual bending, cracks often do not occur even with a smaller bending radius.

On the other hand, for higher-strength high-tensile steel, it is possible that cracks may occur in actual bending with the same bending radius, even if it passes the bending test. This is because the degree of constraint differs between bending test pieces with a narrow width and actual bending with a wide width, making the actual bending more stringent.

Thus, it is important to understand that the bending test evaluates the bendability of the test piece itself and does not guarantee that it will bend at that radius in actual bending.

Physical Properties of SS400

Table 3 shows examples of the physical properties required for the design of SS400. Please understand that these values may vary slightly and are provided for reference.

| Young’s Modulus (GPa) | 206 |

| Shear Modulus (GPa) | 80 |

| Poisson’s Ratio | 0.3 |

| Coefficient of Linear Expansion (×10⁻⁶/K) | 11.7 |

| Thermal Conductivity (W/m·K) | 51.6 |

| Specific Heat Capacity (J/kg·K) | 473 |

| Specific Gravity (g/cm³) | 7.85 |

In summary, we have explained the overview, specifications, standards, and physical properties of SS400.

Did you find any interesting points? Although the name Kumagai Special Steel includes the term “special steel,” we also handle the base steel material SS400. Please feel free to contact us.

In the next volume, vol.2, we will explain important points to consider when purchasing, such as plate thickness, market inventory, and weldability.

We respond to inquiries about steel materials from Japanese steel manufacturers, JIS standard steel materials, special steel materials, and special processing.

We are a specialized trading company based in Japan, dealing in high-tensile steel and other special steels.

Please feel free to contact us.

Feel free to email us.

↓↓↓

mailto:info@kumagai-steel.co.jp

Feel free to email us.

↓↓↓

info@kumagai-steel.co.jp